3xxx Aluminum Coil/Sheet

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Category:

Aluminum Coil

Product Description

Product introduction

Thickness: 0.25-2.5mm

Port of Destination: Any port you like

Technical data

| Alloy | Temper | Thickness(mm) | Width(mm) |

| 3xxx | O/H12/H14/H16/H18/H19/H22/H24/H25/H26/H28/H32/H34/H36/H38 | 0.15-600 | 200-2000 |

Application

As a result of its good property in anti-corrosion, this series aluminum sheet is commonly used in moist environments like air conditioners, refrigerators, at the bottom of cars, etc.

3003 Alloy

It is not heat treatable and develops strengthening from cold working only. Commonly used in chemical equipment, ductwork, and in general sheet metal work. Aluminium 3003 is also used in the manufacture of cooking utensils, pressure vessels, builder's hardware, eyelet stock, ice cube trays, garage doors, awning slats, refrigerator panels, gas lines, gasoline tanks, heat exchangers, drawn and spun parts, and storage tanks.

3004 Alloy

3004 aluminum sheet is commonly used to produce the body of cans, the light components. It can also be used for the processing and storage equipments of chemical products, sheet processing, some construction tools, etc.

3105 Alloy

It has excellent correction resistance, formability and welding characteristics. Besides, it has average mechinability and it can be increased in harder tempers than in annealed condition. The forming characteristics of 3105 aluminum sheet are pretty good by all conventional processes regardless of temper. Typically used for building product applications, it can also be used for other industrial applications.

Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: | Others: | Al: Min. |

| Each | Total | ||||||||||

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.03 | 0.05 | - | 99.7 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99 | |

| 2014 | 0.5~1.2 | 0.7 | 3.9~5.0 | 0.4~1.2 | 0.2~0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | - |

| 2017 | 0.2~0.8 | 0.7 | 3.5~4.5 | 0.4~1.0 | 0.4~0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | 91.5 - 95.5 |

| 2024 | 0.5 | 0.5 | 3.8~4.9 | 0.3~0.9 | 1.2~1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | - |

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | - | - | 0.1 | - | 0.05 | 0.15 | - |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | 0.15 | 0.1-0.2 | - | - | - |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8~1.3 | - | 0.25 | - | 0.05 | 0.15 | - |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.2~0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | - |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | - |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | 0.1 | - | 0.05 | 0.15 | - |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6~3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | - |

| 5A05 | 0.5 | 0.5 | 0.1 | 0.3-0.6 | 4.8-5.5 | - | 0.2 | - | 0.05 | 0.05 | - |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | - |

| 6061 | 0.40~0.8 | 0.7 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | - |

| 6082 | 0.70~1.3 | 0.5 | 0.1 | 0.4~1.0 | 0.6~1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | - |

| 7075 | 0.4 | 0.5 | 1.2~2.0 | 0.3 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.2 | 0.05 | 0.15 | - |

Mechanical behavior

| Tensile strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness(HV) |

| 572 | 503 | 11 | 175 |

Physical properties

| Density | Melting point | Elastic Modulus | Thermal conductivity |

| 2.81 Kg/m³ | 477-635 ℃ | 71.7GPa | 130 W/m.K |

Annealing state

| Trademark | Annealing state |

| 1xxx: 1050, 1050A, 1060, 1100 | O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

| 3xxx: 3003, 3004, 3005, 3105 | |

| 5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 | O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

| 6xxx: 6061, 6082 | T4, T6, T451, T651 |

| 2xxx: 2024 | T3, T351, T4 |

| 7xxx: 7075 | T6, T651 |

Packing and shipping

1. Samples may be provided by the seller and freight borne by the buyer.

2. We have full stock,and can deliver within short time. Many styles for your choices.

3. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

4. All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

5. We have many years of experience in manufacturing and selling steel and we cherish every order from our honor.

HONOR

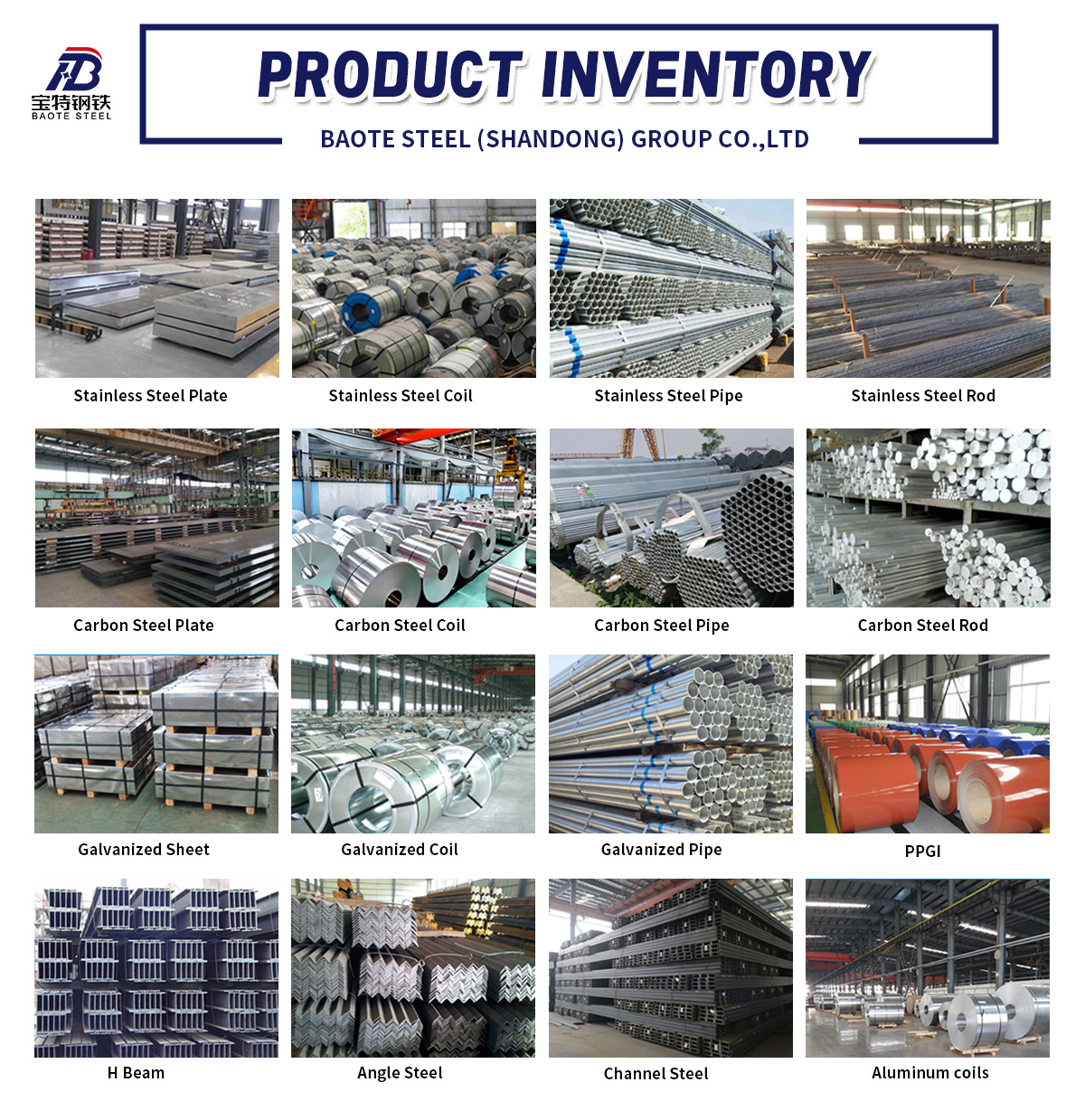

Factory

The company has many traditional advantages: complete variety, sufficient inventory, good quality, low price, short delivery time, good service, etc. It is the designated supplier of many large enterprises, and has provided renovation services for major national projects such as the Forbidden City, the Bird's Nest, and the Water Cube Stadium. Steel available.

Customer Visit

The company has specially built a professional international trade service team with a sales network all over the world. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and have spread to Peru, Philippines, Russia, Ukraine, Belarus, Uzbekistan, Pakistan, Indonesia, Malaysia, South Africa, Sri Lanka, Turkey, Vietnam, Laos , Brazil, Thailand, the Middle East, the United Arab Emirates, Morocco, Spain, the United States, New Zealand, Iran and more than 30 countries.

Applications

Our country is an international steel trade hub. We will connect China's steel resources with world trade demand through high-quality products in a fast, stable and low-cost way. Work with global partners to develop together and achieve win-win cooperation!

RELATED PRODUCTS

MESSAGE