Hot rolled steel round bars

Category:

Steel Round Bars

首页产品

Product Description

16MnCr5 hot rolled steel round bars information

16MnCr5 steel are alloyed case hardening engineering steels for parts which require core tensile strength of 800 – 1100 N/mm² and good wearing resistance. It is an engineering material typically used to manufacture piston bolts, camshafts, levers and other vehicle and mechanical engineering components.

EN 1.7131 steel (16MnCr5 material) is an European standard carburized steel (case hardening steel) with good hardenability and machinability. For larger cross-section parts, high surface hardness and wear resistance can be obtained after heat treatment, and low-temperature impact toughness is also high. For specification and datasheet, please see the tables below.

16MnCr5 steel is generally used after carburizing and quenching, and is mainly used for manufacturing gears, worms, sealing bushings and other components.

Chemical composition

The following table shows chemical composition of 16MnCr5 material (1.7131 steel).

| Chemical Composition % | |||||||

| Standard | Steel Name (Steel Number) | C | Si ≤ | Mn | P ≤ | S | Cr |

| EN 10084 | 16MnCr5 (1.7131) | 0.14-0.19 | 0.40 | 1.00-1.30 | 0.025 | ≤ 0.035 | 0.80-1.10 |

Mechanical Properties of 1.7131 Steel (16MnCr5 Material)

1.7131 material, 16MnCr5 steel Brinell hardness

- Soft annealed: ≤ 207 HBW

- Treated to hardness: 156-207 HBW

- Treated to ferrite-pearlite structure and hardness: 140-187 HBW

- Normalized: 138-187 HBW

EN 1.7131, 16MnCr5 Tensile strength (after hardening and tempering at 200 °C)

- Dia. ≤ 16mm: Min. 1000 MPa

- 16 < Dia. ≤ 40mm: Min. 800 Mpa

- 40 < Dia. ≤ 100mm: Min. 600 Mpa

Heat Treatment Specification of 16MnCr5 (1.7131 Steel)

- End quench test Austenitizing temperature: 870℃ (30-35 minutes)

- Carburizing temperature: 880-980 ℃

- Core-hardening temperature: 860-900 ℃

- Case-hardening temperature: 780-820 ℃

- Tempering: 150 – 200 ℃ (≥ 1 hour)

Packing and shipping

1. Samples may be provided by the seller and freight borne by the buyer.

2. We have full stock,and can deliver within short time. Many styles for your choices.

3. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

4. All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

5. We have many years of experience in manufacturing and selling steel and we cherish every order from our honor.

HONOR

Factory

The company has many traditional advantages: complete variety, sufficient inventory, good quality, low price, short delivery time, good service, etc. It is the designated supplier of many large enterprises, and has provided renovation services for major national projects such as the Forbidden City, the Bird's Nest, and the Water Cube Stadium. Steel available.

Customer Visit

The company has specially built a professional international trade service team with a sales network all over the world. With many advantages, we cooperate with customers in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and have spread to Peru, Philippines, Russia, Ukraine, Belarus, Uzbekistan, Pakistan, Indonesia, Malaysia, South Africa, Sri Lanka, Turkey, Vietnam, Laos , Brazil, Thailand, the Middle East, the United Arab Emirates, Morocco, Spain, the United States, New Zealand, Iran and more than 30 countries.

Applications

Our country is an international steel trade hub. We will connect China's steel resources with world trade demand through high-quality products in a fast, stable and low-cost way. Work with global partners to develop together and achieve win-win cooperation!

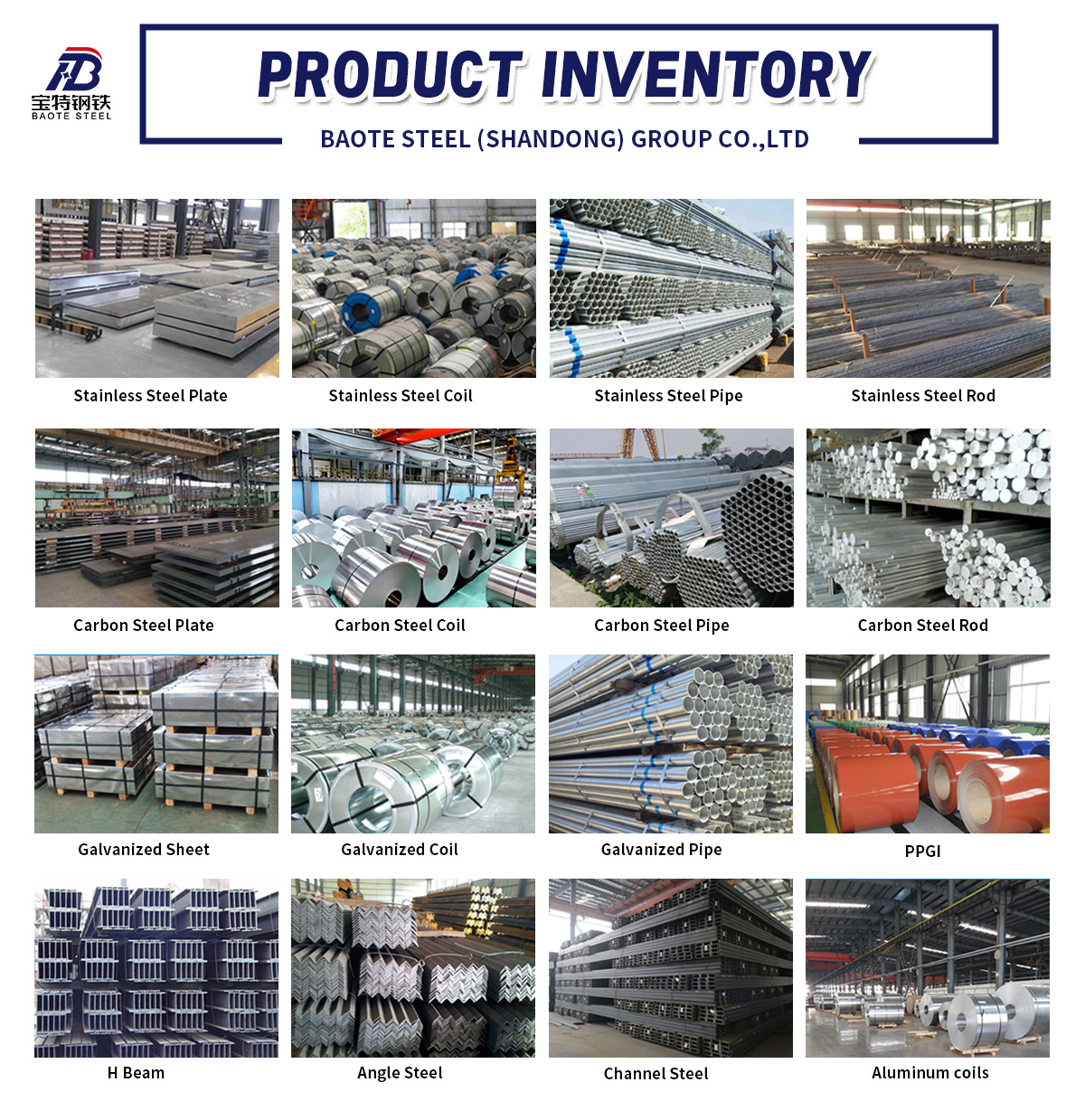

RELATED PRODUCTS

MESSAGE